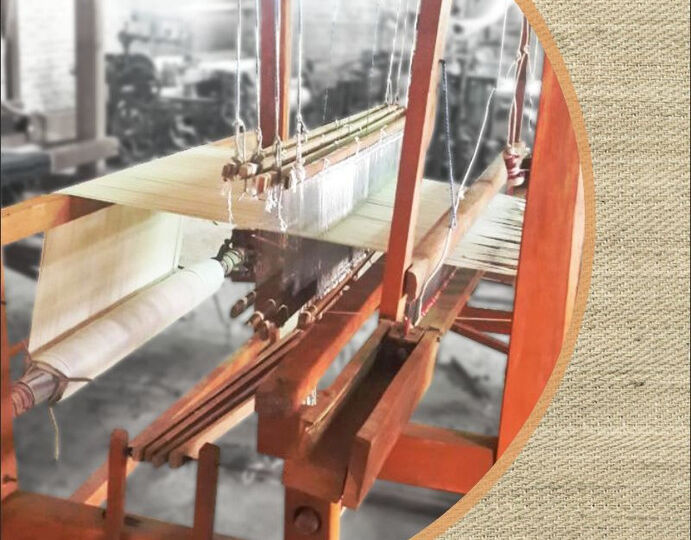

Wooden Frame Handloom

A handloom is a simple machine used for weaving fabrics.

The standard wooden frame handloom is made from pieces of seasoned wood, of appropriate sizes, joined together by way of nails or nut/bolts as per the requirement. A handloom machine – used for weaving fabric – is manually operated, and does not have any electrically operated motor or motorised parts or movements.

The main parts of a wooden frame handloom are:

- Wood frame

- Seat for weaver

- Warp beam

- Back beam

- Rods – used to make a shed

- Heald-wire frame (harness)

- Heald-wire with eye

- Breast beam

- Batten with reed comb

- Batten adjustment

- Sleigh with race board

- Shuttle Boxes

- Shuttle

- Treadles (foot pedals)

- Cloth roll

- Cords

Handloom for weaving Denim

The normal handlooms are primarily used for weaving loosely constructed plain weave fabric in which the warp and weft interlace in a “one-up, one-down” sequence.

However, denim has a different construction, the standard being 3×1 or “three-up one-down”, wherein the weft yarns pass over 3 warp yarns and under one warp yarn in each traverse of the shuttle. This 3×1 interlacing necessitates that the warp sheet is divided into four sets, thereby requiring four independently moving heald wire frames, instead of the normal two.

The Wooden Frame Handloom provided by Denim Club India is specially designed, and most suited for, weaving of denim fabric in 3×1 twill weave construction. The loom is equipped with 4 Nos. foot pedals and 4 Nos. heald-wire frames which are essential for weaving three-up one-down twill weave.

The looms can be used for making denim fabric ranging from 4-5 oz per square yard (170 gsm) to 14-15 oz per square yard (500 gsm) in widths ranging from 36 inches (90 cm) to 48 inches (120 cm).